.jpg)

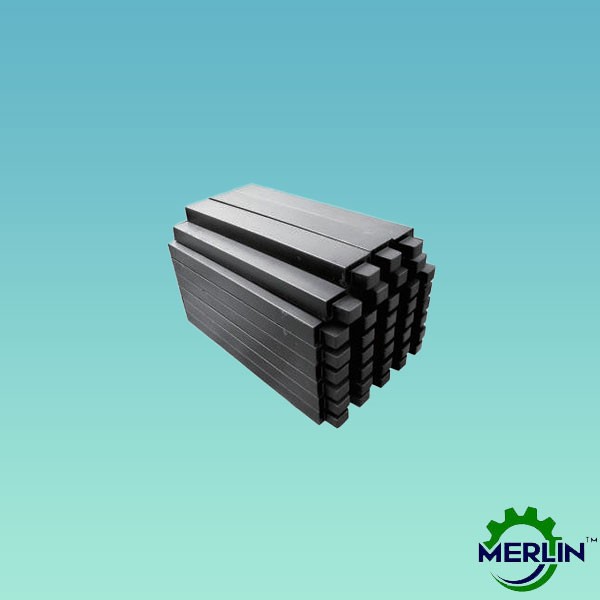

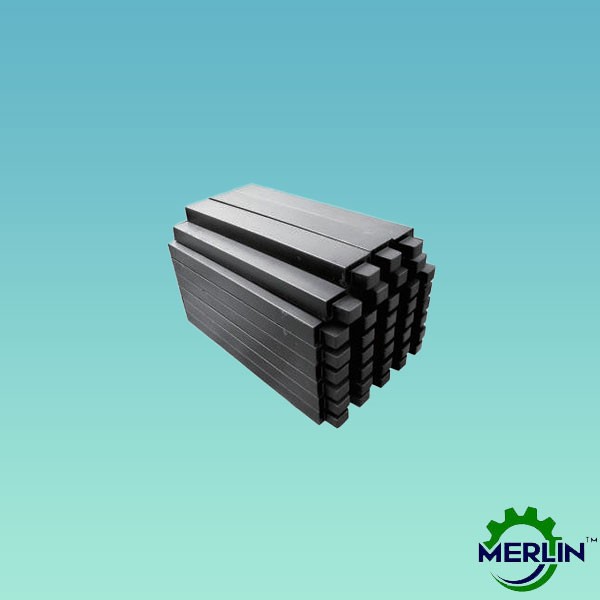

Counter Weight (Steel) in Bangladesh

New elevator construction typically

does not involve lead counterweights. However, when there is a need to increase

the capacity of an existing elevator, installing a new counterweight becomes

necessary. Due to restrictions on headroom, there is often limited space to

increase the stack height of the counterweight. In such cases, lead proves to

be an invaluable solution.

Lead offers a significantly higher

density compared to steel, approximately 45% greater. This allows the upgrading

company to replace the existing steel or cast iron weights with lead

counterweights, achieving the required weight to counterbalance the increased

capacity. With each weight removed, a 45% heavier lead weight is installed,

simplifying the process into a straightforward mathematical equation. Often,

lead is the sole substitute capable of fulfilling this requirement effectively.

In addition to lead counterweights,

Mars Metal manufactures steel counterweights tailored to the specific size and

shape preferences of clients. Our offerings include custom sizes as well as

standard OEM weights, available in any quantity. Utilizing production cut steel

plates sourced from Cobble, Secondary Plate, and Coil, we ensure the lowest

costs without compromising on quality.

The Steel Counter Weight represents

an integral element within elevator systems, meticulously engineered to

facilitate safe and efficient vertical transportation. Crafted from robust

steel materials, this specific counterweight serves as a crucial component,

effectively balancing the weight of the elevator car, passengers, and cargo.

Installed within the elevator

shaft, the steel counterweight is strategically calibrated to counterbalance

the car's weight, ensuring smoother and more controlled movement. Its

construction from steel, renowned for its strength and durability, enables it

to withstand substantial loads while maintaining stability and reliability.

Precision engineering allows for

accurate adjustment and alignment of these steel counterweights, guaranteeing

optimal balance to minimize strain on the elevator motor and facilitate

energy-efficient operations.

Apart from its role in balancing

the elevator system, the steel counterweight acts as a vital safety measure. By

stabilizing weight distribution, it prevents overloading and assists in

regulating the speed of the elevator car, contributing significantly to

passenger safety.

Expertly installed and calibrated

to meet stringent safety standards, steel counterweights undergo rigorous

testing to ensure their reliability and adherence to industry regulations.

Their pivotal role in enhancing elevator performance and safety makes steel

counterweights an indispensable component in providing passengers with a secure

and smooth vertical transportation experience.